| Greg's Fujitsu air conditioners |

|

||||||

|

|

|

|||||||||||

In September 2007 we installed two Fujitsu split system reverse cycle air conditioners to heat and cool our house in Dereel. They had a total of 7 internal units connected. We had a lot of trouble getting them to work properly; that didn't happen for over a year. The problem was simple, but diagnosing it was a major pain.

On this page I'll summarize the problem, and then add commented extracts from my diary describing how things “progressed” (for want of a better word).

|

|

|

This page needs revision. The problems described here are long gone, but a more serious problem remains: it's almost impossible to control the temperature, because the temperature control system measures the temperature in the wrong place. There's no obvious solution for this one, especially since nobody seems to understand that there is a problem.

This information is included below. You just have to find it.

The cause of the problem was simple: one of the external units was supplied with approximately double the correct amount of refrigerant. This caused the units to heat or cool much less effectively than they should have done, to the point where the external unit would shut down for extended periods when it should have been heating.

So why didn't we find this out earlier? There are a number of issues:

Despite the modern design of the compressor itself, the user-visible controls are firmly rooted in the mid-20th century. The temperature sensors are located at the right of the internal unit, and out of the air flow, above the pipe sensor!

|

|||||||||||||||||||||||

|

|

|||||||||

This is obviously the wrong place to measure the temperature (what user cares what the temperature is there?). To control the temperature, you need to find out what the current value of that temperature is. There are many ways, starting with guesswork, superstition or phase of the moon, but the obvious way is to measure it: the temperature in the room, not any temperature in the unit which is generating the heat.

Instead, though, Fujitsu measures the temperature where it's convenient for them and use that value to try to guess the temperature in the room. I'm reminded of the joke attributed to Josef Weizenbaum:

A policeman saw a drunk searching for something under a lamppost. “What have you lost?” the policeman asked. “ My keys”, said the drunk. The policeman then helped the drunk look and finally asked him: “Where exactly did you drop them?” “Over there”, responded the drunk, pointing toward the dark street. The policeman then asked: “Why are you looking here?” The drunk replied: “Because the light is so much brighter here.”

It seems that most manufacturers of split-system air conditioners make this trade-off. But Fujitsu makes it even worse: the temperature sensors are located out of the air stream, and directly above the pipe sensor (the diagonal copper pipe in the detail photos; the sensor is the black element above it). The pipe sensor measures the temperature in the coil, which should be about 50°. The temperature range for the room is limited to 16°-30° when heating, or 18°-30° when cooling. And since warm air rises, the air temperature above the pipe sensor during heating will be artificially high. Since there's no air flow, there's no way for this temperature difference to dissipate.

This problem doesn't occur when cooling, since the pipe sensor will then have temperatures below 10°, and air flow around it will go in the opposite direction. I'm left with the feeling that Fujitsu started with a design for a cool-only device and then modified it for heating without doing their temperature measurement homework. This hypothesis is borne out by the fact that the unit is manufactured in Thailand and is available in a cool-only version. The serial numbers of my external units (1973 and 1974) also don't suggest that many of them are sold.

This problem wasn't just theoretical: even on the unit that seemed to be functioning normally, the temperatures could not only be up to 3° off from the set point, but they also wandered depending on the outside temperature. Clearly Fujitsu's guesswork isn't good enough.

As a result of these considerations, I was convinced that the problem was one of temperature control; the only problem was that it only happened with one unit, and the effects were so bad that other people would complain too.

I spent a lot of time trying to analyse the problem before finally getting somebody to come and look at it. That was Tony Nesci, since Phil Pilmore is now doing only industrial work. Tony was hampered by a number of problems:

He didn't have any maintenance documentation for the unit. That included finding out what the LED display on the controller board meant. He called Fujitsu's service centre, but they didn't know either.

When we did find out the meaning, it was simple: “head 4 not connected”. That's correct information—this unit only has 3 internal units connected—but why isn't it saying why it stopped?

Nowadays every car has electronics that not only control specific functions, but also monitor and log problems that occur in normal operation. It seems that air conditioners don't do this sort of thing. The amount of information you can convey with 4 LEDs is limited, but if a $200 laser printer can have an Ethernet interface and an on-board web browser, then surely an air conditioner can. There have been a total of 6 visits to resolve this problem; that makes well over $1000 in costs (fortunately not to me). It seems ridiculous that they don't invest in more modern diagnostic procedures.

The remainder of the diagnosis was based mainly on guesswork: he replaced the control electronics (with a board which had been sent with inappropriate packaging and damaged in transit, not an advertisement for Fujitsu), on Fujitsu's recommendation he topped up refrigerant—as we know now, about the worst thing to do—and he even suspected line voltage problems. The decision to check the refrigerant was done just before replacing the unit, not because of any diagnostic information, but simply because it hadn't been checked before. Nobody was expecting it to work. In other words, a complete breakdown of the system.

In July 2008, before we found the problem, I wrote the following:

Almost as soon as they were installed, it was clear there was something wrong. The specifications looked great, and the price was acceptable. I have every reason to believe that they work well and efficiently.

But the temperature control is abysmal! We have had temperatures off by over 10°, almost the complete range of temperatures that the things can handle, but only when heating. The temperature accuracy when cooling seems acceptable, though not good. Early on I came to the conclusion that the real issue was that they were measuring the temperature in the wrong place; on 12 July 2008 I did some investigative work with Phil Pilmore, the installer, and found much evidence to support this theory.

The following are relevant entries from my online diary on the subject. Considering that the installation was complete at the end of September, it's clear that the problem has existed since the beginning.

The following (rest of this page) consists of relevant extracts from my on-line diary, along with some comments based on hindsight.

| Thursday, 20 September 2007 | Today's diary | Today's images | top | next | last |

Phil Pilmore of White Swan air conditioning came along today with his crew to finally install the air conditioners:

|

|||||||||||||||||||||||

That took them all day, and at the end of it they still weren't finished, but finally we're on the way to civilized temperatures. Spent the day tidying up in preparation; I also didn't get finished.

| Friday, 21 September 2007 | Today's diary | Today's images | top | previous | next | last |

Phil back today to finish the installation of the first air conditioning unit. We have heating again! What a relief!

| Tuesday, 25 September 2007 | Today's diary | Today's images | top | previous | next | last |

Phil and Ryan came along today to finish the air conditioner installation—they had been called out on an emergency yesterday. Now everything's finished, and the house is warm—almost too warm; I suspect that Fujitsu is not measuring the air temperature that interests me.

| Thursday, 25 October 2007 | Today's diary | top | previous | next | last |

See the beginning of this page for clarification. While I stand by the comments I've made (and indeed repeated them above), they weren't the reason for the most serious of the problems we were experiencing.

We've had our air conditioning for a month now, and on the whole it works well. Looking at the relatively technical brochures that Fujitsu print about the technology of the air conditioning units themselves, it seems a real shame that they go and break it with some of the most stupid decisions on room temperature control.

Measuring the room temperature is more complicated than it seems. In fact, there is no such thing as “room temperature”; the temperature in any room with air flow varies greatly from one place to another. So clearly the place where you measure it is of great importance. It should be clear that the place to measure it is where the occupants of the room measure it—ideally on the surface of their skin, but a good approximation is close to where they are.

Instead, Fujitsu measures the temperature of the “return air”, the air being sucked in to the interior unit for heating up. The best you can say about measuring there is that it's not as bad as measuring the output air, which necessarily needs to be warmer. But when heating a room by air convection, no matter how the heat is created, the hot air tends to rise to the ceiling, and that's where the return air is.

This makes it almost impossible to control the room air temperature. We like to have the temperature round 21° in the day time, and for some reason which I haven't completely investigated, we get this by setting the temperatures on the units to 19°. But in the evening we like it one or two degrees warmer, and we just can't get it! The highest setting of the thermostats is 30°, and when we set that, we end up with the air at the ceiling warming up to 30°, after which the units cut out. I've measured the air temperatures in the room at this point; they show a strong temperature gradient, dropping to about 17° near the floor, and hitting about 21° to 22° in the vicinity of the arm chairs, barely warmer than when the thermostats are set to 19°. Clearly an improvement in air flow could help, but equally clearly the temperature control just doesn't work, because Fujitsu has chosen the wrong place to measure the temperature. I'm sure the engineers are very aware of this, but it's marginally cheaper to measure in the wrong place, so I'd guess that this is another triumph of marketing over sound engineering. Once again I'm reminded of the joke attributed to Josef Weizenbaum:

A policeman saw a drunk searching for something under a lamppost. “What have you lost?” the policeman asked. “ My keys”, said the drunk. The policeman then helped the drunk look and finally asked him: “Where exactly did you drop them?” “Over there”, responded the drunk, pointing toward the dark street. The policeman then asked: “Why are you looking here?” The drunk replied: “Because the light is so much brighter here.”

Before I get mail telling me that maybe the units are not powerful enough: that's not the problem. The thermostats cut out completely (an extreme situation for an “inverter” system), and the measurements indicate that this is because they've achieved their goal temperature.

| Wednesday, 21 November 2007 | Today's diary | Today's images | top | previous | next | last |

One of the consequences of the drop in temperature is that we're now heating instead of cooling. And once again the temperature control of the air conditioners appears to be non-existent. After several hours of “heating” with the thermostat set at the maximum, the temperature was 21° at table top height and 19° on the floor:

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

| Thursday, 3 April 2008 | Today's diary | Today's images | top | previous | next | last |

The weather is getting cooler, and it's becoming increasingly clear that the temperature control of our Fujitsu air conditioning is not just bad, it's completely broken. It only has a scale between 16° and 30° (18° to 30° when cooling, barely enough if it were correct), but it can be off the correct mark by up to 10°. In the evening I had to set the temperature to 30°, and even then it cut out when the room temperature hit 20° to 21°. Time to get Phil in to take a look. The problem's pretty clear: it's measuring the temperature in the wrong place, somewhere inside the indoor unit, instead of in the room.

| Friday, 13 June 2008 | Today's diary | top | previous | next | last |

Winter is gradually coming, and with it the problems I've already mentioned with my air-conditioning system are becoming more acute. Finally decided to do something about it and called Fujitsu on the number specified, 1 800 226, 347. No reply—I just got an answering machine, so I left a message.

There was another link, of course, giving a number in Sydney (no free call), +61 2 8822 2500. Called that; it took three attempts to get connected, and with a bit of trouble they gave me the phone number of Angow and Hutt in Ballarat.

In the meantime, Brian called back responding to the first message and told me that they were Fujitsu, and they didn't do air conditioners—that was Fujitsu General, a different company. But where's the link from that page? Where's the overview? He also gave me the number 1 300 882 201, which isn't mentioned anywhere on that page, nor in the phone book.

Called up Angow and Hatt, left a message and got a call back from Colin Angow, with whom I had already spoken last winter. Spent about 40 minutes on the phone explaining the situation, which he suspects could be an “application design” issue, although he couldn't say why. He didn't completely reject the idea that the problem was that the system was measuring the wrong variable, but he didn't seem to be very keen on believing it either. About the only concrete things that came out of it were:

I would have to pay $60 for him to come and look at it, not even refundable if it proved to be Fujitsu's fault.

It should be possible to move the position of the sensor elsewhere, though Fujitsu don't support this concept.

There's a DIP switch somewhere on the controller that sets a fixed offset of 4° between reverse air temperature and set temperature. It can be disabled.

He also claimed that the “Auto” position on the heating/cooling selection disabled the temperature sensor and set a fixed 20° temperature. I have difficulty believing this, but I suppose anything's possible.

| Saturday, 12 July 2008 | Today's diary | Today's images | top | previous | next | last |

Phil Pilmore finally made it here this morning and took a look at the air conditioners. To my surprise—and, I think, to his—there was nothing wrong with the units beyond some ants nesting in the outside unit.

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

Phil tells me that they can really mess up circuit boards, as I can easily imagine. It's surprising that the manufacturers don't take care to keep them out, and even more so that vermin damage is excluded from warranty claims.

So it looks like it's something to do with the temperature regulation after all. Took off the cover of one of the units to look for the temperature sensor. It's the shiny black blob in the middle of the photo (this is the same photo with different cropping):

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

|

|||||||||

That copper pipe directly below it is the coil temperature sensor, and when heating it normally reaches temperatures of round 50°. As the first photo shows, it's not directly in the air flow, so warm air convecting from the pipe sensor can, at least in theory, strongly influence its readings—exactly the situation that I have been postulating. It is also unlikely to be an issue when cooling, which also fits my observations.

As they say, for every complex problem there is a solution that is simple, elegant—and wrong. It's too early to say that this is the cause of the problems, but it's certainly a bad design decision. It's bad enough to put the temperature sensor in the return air at all. But here it's not in the main flow of the return air, and it's in direct proximity of a component that is in the order of 30° hotter than the return air. More experimentation needed.

After Phil left, did some more thinking, and a bit of experimentation. Looking at the unit with the cover on was puzzling: there seems to be no way to get air flow across the sensor:

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

The sensor is behind the small grille to the right, but there's no way I can see to pull the air past. Is this even an ambient temperature sensor? If so, they've done what they can to make it ineffective. Pulled off the cover and measured the temperatures; the pipe was 50°, as expected, and the area above it about 28°, close to turning the thing off. Put an old punched card between them:

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

That seemed to bring some improvement; at least the unit kept running, whereas before it would cut out all the time. But that's just the beginning of the experimentation.

| Thursday, 17 July 2008 | Today's diary | top | previous | next | last |

More playing around with the air conditioners today, and did what I should have done a long time ago: checked how much air flows past the temperature sensor. As I had suspected, there is none. This means that the temperature sensor is subject to two influences: air convection through the double grille separating it from the air under the ceiling—normally the warmest—and any heat generated in the immediate vicinity, in this case the pipe sensor immediately below it, which will tend to warm the sensor. Under those circumstances, it's not surprising that the temperature control is so lousy.

The only question is, why? I can't imagine that the Fujitsu designers are really that stupid. I can see a number of explanations:

I'm wrong (and so is Phil): the device I'm looking at is not the temperature sensor, which is mounted elsewhere. But there aren't many places where you could put it, and we didn't find it elsewhere.

This is a marketing decision, not an engineering decision. The units were originally designed for cooling only (cooling-only variants are in fact available). The sensor location might work relatively well for a cooling-only unit, but the marketing people decided to market a unit that can also heat without paying attention to the sensor location.

The other issue I have is: how can they get away with it? Am I the only person who notices these things?

| Friday, 18 July 2008 | Today's diary | Today's images | top | previous | next | last |

Peter Jeremy commented on IRC about the location of the temperature sensor in Fujitsu air conditioners. He has one too, and he sent me a photo:

|

|||||||||||||||||||||||

The black device at the top right of the coil is the temperature sensor, about the best place you can put it if you insist on putting it inside the unit. So why do mine have the sensors hidden in such an idiotic place?

| Monday, 1 September 2008 | Today's diary | top | previous | next | last |

Tony Nesci from Atmos in today to look at the air conditioners. He confirmed that yes, the temperature sensors were not in the most obvious place, though he was careful not to say that the place was stupid. But he investigated elsewhere and came to a more plausible solution: the control electronics in the external unit were defective, causing it to cut out every so often. That's inspired guesswork, of course: Fujitsu, like other manufacturers, provides no tools for confirming the function of the electronics. Wouldn't an Ethernet interface and a laptop with software make all the difference? In any case, the diagnosis fits the facts, so he'll replace the controller some time next week and take it from there.

| Wednesday, 17 September 2008 | Today's diary | Today's images | top | previous | next | last |

Tony Nesci came along with the replacement circuit board for the air conditioner. In the process, he discovered something disconcerting about the old one:

|

|||||||||||||||||||||||

One of the chips was covered in ants. Why doesn't Fujitsu ant-proof their units? It's as simple as a water gap. But were they the cause of the problem?

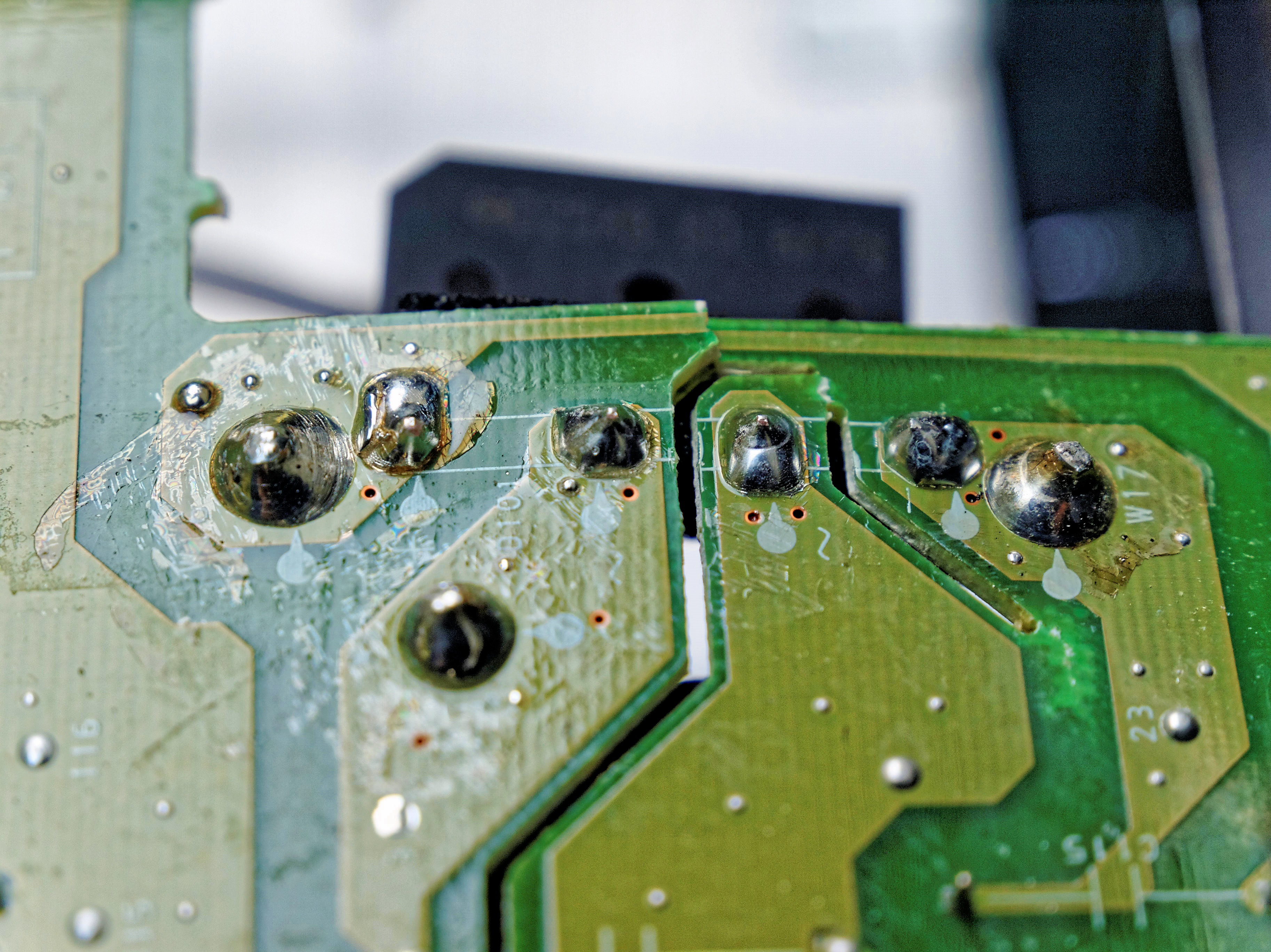

First, we had to install the new board. That proved to be damaged, presumably because it had been shipped in a completely inappropriate container:

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

That and the obvious construction deficiencies certainly don't give me the warm fuzzy feeling that they know what they're doing. But it looked as if the damage wouldn't stop it from working, so Tony installed it. We were able to confirm that it made no change whatever: the problem was still there, so neither the ants on the old board or the crack in the new board had any effect. In the process, discovered that there are 4 LEDs on the board to display error status (bottom of the photo), but that nobody knows what they mean. What kind of nonsense is that? Tony did a bit more checking, but effectively his hands are tied because Fujitsu doesn't have adequate error reporting techniques and policies.

| Wednesday, 8 October 2008 | Today's diary | top | previous | next | last |

Tony Nesci along to take another look at the air conditioner problems. He found a minute leak which accounted for about 1.05 kg of R412A refrigerant, and fixed that, convinced that that was the problem. I felt quite sorry for him when it proved not to be the case. After further discussion with Fujitsu, they've decided to replace the whole unit. Isn't that an expensive alternative to providing useful diagnostic tools? The problem is that the unit cuts out when it should continue heating; all you need is some kind of logging that explains why it cut out.

| Wednesday, 22 October 2008 | Today's diary | Today's images | top | previous | next | last |

Tony Nesci along round midday with yet another approach to fixing the air conditioner: he removed all the refrigerant, weighed it and refilled with the correct amount. That was well worthwhile: according to the specifications panel, the correct charge should be 3.3 kg; in fact, he removed 6.7 kg:

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

That included the 1.05 kg that he put in—on Fujitsu's instructions—a couple of weeks ago. After replacing the 3.3 kg, the machine worked!

What's wrong with this situation? Many things:

Clearly the unit was shipped with far too much refrigerant. That's an obvious quality control issue. I've seen the leak that Tony found, and it's clear that there was once even more refrigerant in the unit.

The advice from Fujitsu to add even more refrigerant was wrong.

The unit just failed without any indication of why.

The problem is a “traditional” one—it's existed for as long as heat pumps. But everybody, myself included, blamed the new-fangled electronics. Given the fact that it didn't report the problem, despite the fact that it's a relatively common one, our distrust wasn't completely unfounded, of course.

Today Tony finally arrived with documentation for the unit. If he had been given that earlier, it wouldn't have taken quite as long to solve the problem.

Even the information on the specification panel is not beyond doubt. It also states that this unit is for 240 V supply; in fact, Australian mains are 230 V. It's possible that the unit is really not correctly matched to the Australian power system, but I suspect that it's simply sloppy documentation. Nobody goes and changes the voltage input based on that panel, but air conditioner technicians will charge the 3.3 kg based on the panel.

From my own point of view, it's clear that I, too, had jumped to the wrong conclusions. I'll have to completely rewrite my product review in light of this information.

| Thursday, 23 October 2008 | Today's diary | Today's images | top | previous | next | last |

Peter Jeremy commented on the air conditioning saga, and asked about how much refrigerant is required for the tubes connecting the inside units to the external units. In our case it's considerable. The answer (which Tony Nesci told me last time he was here): 30 g per 3 metres. If this sounds like a roundabout way of saying “10 g per metre”, you need to understand that it's “metric”; it almost certainly used to be “1 ounce per 10 ft”, and it applies to the distance between the units, not both tubes. With the amount we're talking about here, it would make about 300 g. But in this case, Fujitsu have explicitly stipulated that no extra refrigerant should be added.

| Greg's home page | Greg's diary | Greg's photos | Copyright |